If the cement industry were a country, it would rank as the world’s third-largest carbon emitter, behind only China and the United States. Cement production alone accounts for nearly 8% of global CO₂ emissions, making it one of the most critical yet overlooked targets in the fight against climate change. Despite a surge of interest in “green construction,” truly scalable solutions have remained out of reach. That may finally change.

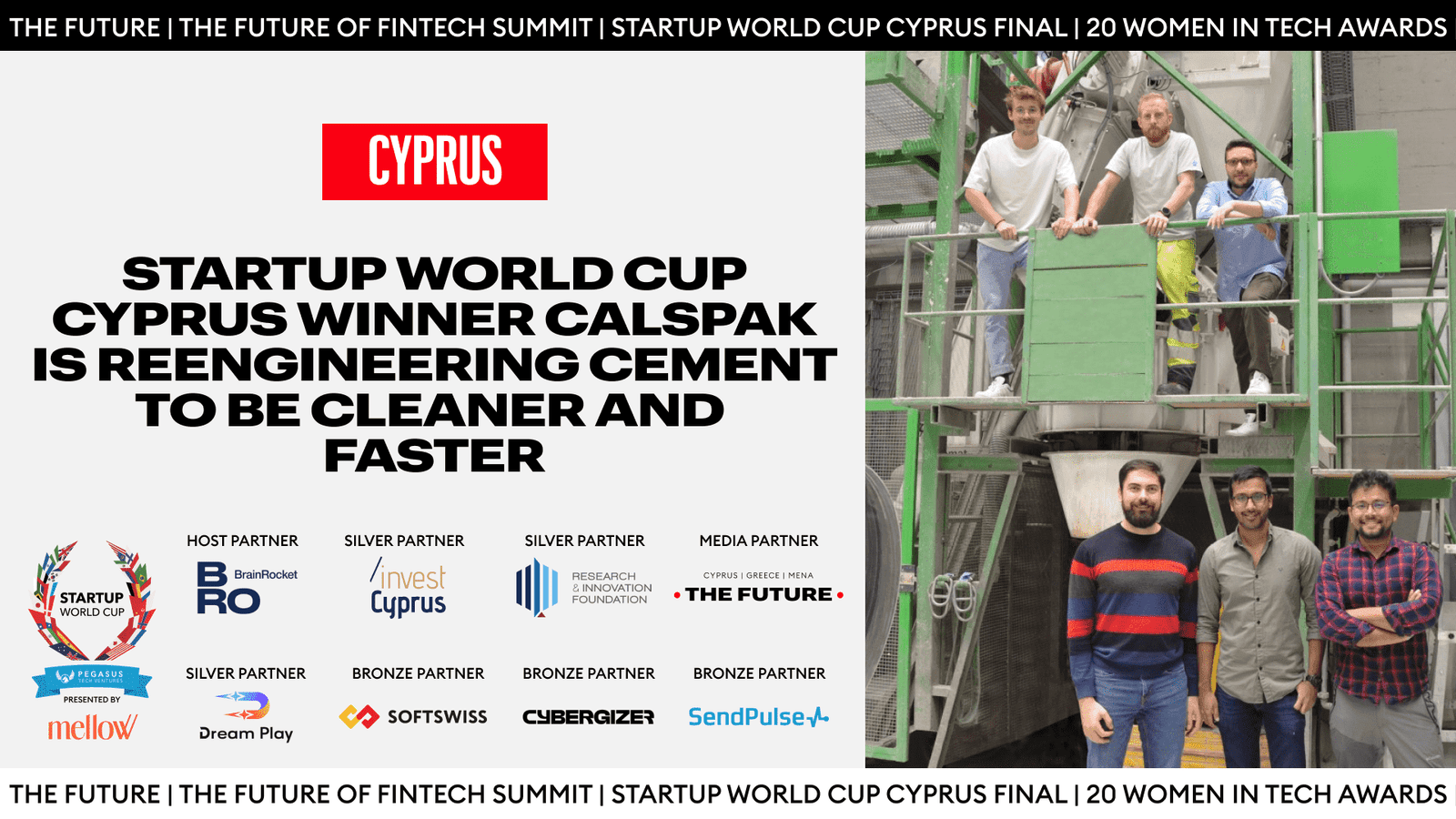

From Cyprus, an ETH-based startup called Calspak is gaining traction with a technology that doesn’t just promise lower emissions, it offers faster construction timelines and improved material performance. Their recent win at the Startup World Cup Cyprus finals earned them a spot at the $1 million global finale in San Francisco at a moment when construction materials are under more scrutiny than ever for both their climate impact and commercial viability.

Follow THE FUTURE on LinkedIn, Facebook, Instagram, X and Telegram

When Research Meets Industry

The Calspak story begins in the labs of ETH Zurich. CEO Dr. Arnesh Das and co-founder Dr. Ioannis Koureas first crossed paths at the Institute of Building Materials (https://ifb.ethz.ch/) during their PhD studies, working in adjacent research groups that would ultimately converge on a shared vision.

Dr. Das’ doctoral research focused on developing fast-reacting cement formulations specifically for 3D concrete printing, work that would later evolve during his postdoctoral studies into broader applications for low-carbon, fast-reacting cement systems enhanced with special chemical admixtures. What began as academic curiosity soon revealed commercially viable breakthroughs.

“The developments turned out to be not only scientifically promising but also practical and scalable,” explains Dr. Koureas. “From our interactions with industry, we received positive feedback that motivated us to commercialize our technology.”

This early industry validation proved crucial. Rather than developing their solutions in isolation, the founders worked closely with manufacturers to ensure their product addressed real market needs. This approach became central to their commercialization strategy.

What’s in a Name?

Even the name “Calspak” reflects their scientific discipline. When asked about the origin of the name, Dr. Koureas points to the chemistry:

“The novelty of our technology lies in a unique calcium (Ca)-aluminate (Al)-sulfate (S) binder system; that is where CALS comes from. Our mission is to provide a whole material package (PAK) and develop customized formulations for a wide range of concrete products.”

The name isn’t just technical shorthand. Rather, it points to the company’s deeper focus: moving away from traditional Portland cement—the industry’s dominant binder for over a century—and designing an entirely new binder system built for speed and sustainability.

Performance That Speaks to the Bottom Line

Unlike many green tech solutions that prioritize environmental goals at the expense of performance, Calspak understands that sustainability alone won’t drive industry adoption. That’s why their formulation delivers practical advantages, including faster turnaround times, lower costs, and better output, that speak directly to manufacturers’ priorities.

“We combine low-carbon cement with specialized chemical admixtures to reduce greenhouse gas emissions while significantly accelerating hardening in the first hours and days,”

says Dr. Koureas.

In the precast concrete market, where production time directly impacts revenue, Calspak’s technology enables demolding in just 4-6 hours compared to the industry standard of 10-12 hours. That is a 50% faster strength gain, translating to higher productivity and shorter delivery times for manufacturers.

But the innovation doesn’t pause at speed. Their formulation also accommodates high volumes of supplementary cementitious materials (SCMs), locally sourced and low-carbon alternatives to traditional cement. This reduces material costs, supports local economies, and decreases emissions without compromising performance.

For manufacturers, this combination of faster processing means, reduced inventory holding costs, and the ability to meet tighter delivery schedules creates a strong business case to justify any premium for sustainable materials.

The Competitive Landscape

As global interest in low-carbon construction grows, Calspak finds itself competing with both large cement manufacturers and niche chemical admixture developers. Yet the team sees clear advantages in their approach.

“Most low-carbon cements currently available face limitations around long-term raw material availability and cost, range of applicability, and incompatibility with state-of-the-art chemical admixtures. Our results thus far have been quite encouraging, and we strongly believe we can overcome these limitations.”

explains Dr. Koureas.

It’s a position likely to resonate with an industry wary of disruption, offering a path to lower emissions without scrapping existing production models. For many manufacturers, that balance between innovation and operational continuity could prove far more persuasive than climate benefits alone.

From Research to Market: Building Commercial Momentum

The transition from laboratory breakthroughs to commercial success requires more than innovative technology. Through Horizon Europe’s Convert2Green program, Calspak has been systematically building the foundation for market entry: conducting comprehensive life cycle assessments, refining pricing models for European markets, and gathering crucial market intelligence.

Their participation in the Startup World Cup Cyprus finals reflected this strategic approach to validation. “We joined to test ourselves against top-tier startups, gain feedback, and build connections,” explains Ioannis. “Winning wasn’t our immediate priority; rather, we aimed to learn, gain traction, and validate our vision.”

The experience delivered beyond expectations. “The environment was collaborative, with jury members providing guidance to strengthen our pitch and messaging for global stages,” he adds. More importantly, the positive reception confirmed they’re developing a solution the market genuinely needs.

This external validation has been crucial for a team operating in an industry known for its conservative approach to innovation. Construction companies need proof that new technologies won’t compromise quality or reliability, concerns that awards and expert endorsements help address.

The Million-Dollar Opportunity

As Calspak prepares for the Startup World Cup Grand Finale in San Francisco, their focus reflects hard-won lessons about scaling deep tech innovations. They’re advancing new pilot projects, gathering additional customer insights, and refining their presentation for both technical and non-technical audiences.

Perhaps most crucially, they’re enhancing their communication strategy to reach the traditionally conservative construction sector while emphasizing the urgency of change. This balance—respecting industry caution while conveying climate urgency—will be essential for widespread adoption.

Should they secure the $1 million prize, their priorities are clear and focused: complete necessary certifications, expand their R&D team, and scale pilot projects across target markets. These investments reflect their understanding that sustainable technologies must meet the same rigorous standards as conventional alternatives.

Market Entry: Switzerland as the Proving Ground

That balance is reflected in how Calspak is entering the market. They are initially targeting the precast concrete market in Switzerland and neighboring countries, markets characterized by high performance standards and regulatory sophistication.

“After validating our product and technology at scale in these markets, we plan to enter the ready-mix concrete market as well and rapidly scale to the rest of Europe and beyond.”

Dr. Koureas notes.

This approach offers several advantages. Switzerland’s demanding quality requirements will stress-test their technology, while the country’s environmental consciousness creates receptive conditions for sustainable innovations. Success there will provide credible references for expansion into larger European markets.

The precast focus also makes strategic sense. These manufacturers operate under controlled conditions that favor new technologies, unlike ready-mix concrete operations that must perform reliably across diverse field conditions. Building credibility in precast applications creates a pathway to the larger ready-mix market.

Beyond technical innovation, Calspak is taking a methodical path to the market. Through the Convert2Green program, the team is conducting life cycle assessments, testing pricing models, and researching market demand across Europe.

Their participation in the Startup World Cup Cyprus was part of this broader strategy.

“We joined to test ourselves against top-tier startups, gain feedback, and build connections. Winning wasn’t our immediate priority; rather, we aimed to learn, gain traction, and validate our vision.”

explains Dr. Koureas.

“The environment was collaborative, with jury members providing guidance to strengthen our pitch and messaging for global stages,” he adds.

The result? A win, plus new contacts and credibility in a sector known for its cautious adoption of new technologies.

What Comes Next

As Calspak prepares for the Global Finale in San Francisco, they’re focused on four key areas:

- Advancing pilot projects

- Gathering customer feedback

- Tailoring their pitch for mixed audiences

- Refining communications to appeal to a traditional industry with urgent needs

Looking ahead, Calspak’s ambitions extend far beyond company growth to industry transformation. “We envision Calspak as a recognized global brand in sustainable cement,” says Dr. Koureas. “Providing a portfolio of green cement solutions with enhanced performance for precast and ready-mix concrete markets.”

Their ultimate goal reflects the scale of the challenge: “We aim to redefine industry standards by enabling rapid, low-carbon construction at scale, contributing significantly to global emission reductions while making sustainable construction mainstream.”

Whether they win the $1 million prize or not, their early traction is a great example of how research, strategic market focus, and industry engagement can work together to address global challenges. Even in a sector historically resistant to change, they are proving that with the right approach, even cement can evolve rapidly.

For an industry that literally builds the foundation of modern civilization, that’s a breakthrough worth building on.